Within the toll refining process, the price calculation for your material is based on an exact wet-chemical ICP-OES analysis. Different options at the due date of the precious metals offer highly flexible payment models. A material safety data sheet (MSDS) is required for ensuring the reliable processing of your material.

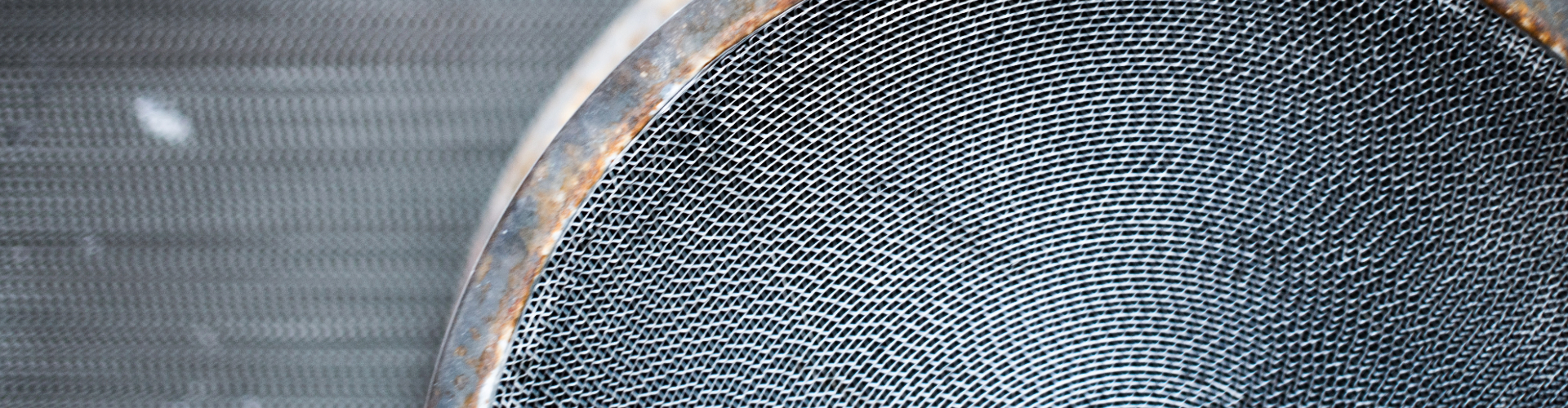

As soon as your products arrive at our site, their exact weight will be determined and allocated to the relevant contract. In the first processing step, the catalytic converters are dismantled before they are processed in modern recycling facilities and a homogeneous powder is generated. Following the homogenisation phase, the collected material sample is prepared in our lab for precious metal analysis.

One of our most important core competencies is the preparation of samples. All processing steps such as the homogenization and sample taking meet clearly defined standards and are reproducible at any time. A sample of approx. 100 grams, which is analyzed in the lab for its precious metal content, is representative of several tons of material.

Using the latest analysis methods, we ensure precise valuation of your materials. XRF analysis as well as wet-chemical methods will provide you with a reliable calculation basis.

The ICP-OES analysis offers many advantages. However, it is time- and cost-intensive, which makes toll refining especially well-suited for larger volumes.

For ceramic catalytic converters, we offer an instalment payment option after processing on the basis of an X-ray fluorescence analysis (XRF).

Convince yourself of our technical know-how and our many years of expertise in precious metal recycling.