Since our founding, we have continuously invested in new technologies and processes for the economic recycling of scarce raw materials and the sustainable preservation of our livelihoods.

RESEARCH AND DEVELOPMENT

BEST4HY H2020 PROJECT

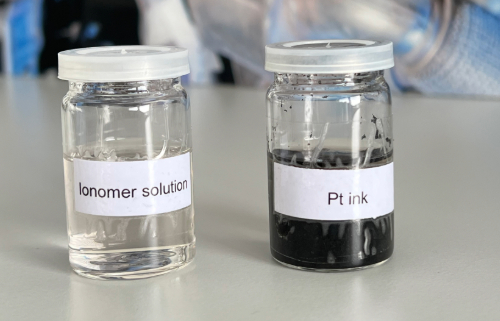

BEST4Hy stands for "SustainaBlE SoluTions FOR recycling of end-of-life Hydrogen technologies" and is a research project funded by the Fuel Cells and Hydrogen 2 Joint Undertaking (now Clean Hydrogen Partnership) under grant agreement no. 101007216. The aim was to develop environmentally friendly technologies for the recovery of raw materials relevant to the supply chain of hydrogen technologies.

As demand for hydrogen technology increases, ever more devices become in use and will eventually end up in the waste stream, requiring therefore to be handled in a sustainable manner. However, according to the findings of previous research initiatives, there are very few examples of viable and up-scaled technologies for the recovery and recycling of critical raw materials from fuel cells (FCs) and electrolysers.

BEST4Hy focuses on the development and validation of existing and novel recycling processes for two key fuel cell and hydrogen products: proton exchange membrane fuel cells (PEM FC) and solid oxide fuel cells (SOFC). The project aims to adapt two existing recycling processes applied already to other technologies and to validate a novel dismantling process for PEMFC. Furthermore, a novel SOFC recycling technology will be proved. At the end of the processes, the materials will be validated in terms of quality and performance when re-used in new components and in new stacks, demonstrating the overall efficiency of recycling. Ambitious targets for recycled content in new stacks/cells have been set and will be validated by fuel cell producers, to prove the viability of higher value, closed loop recycling. Environmental impact and cost-benefits evaluations on the proposed technologies will be performed. This will support a more efficient use of raw materials, including critical resources, and it will contribute to improve the end-of-life treatment of the hydrogen technologies and to foster a circular economy approach within the sector.

BEST4Hy international consortium is composed by industrial partners and research institutes:

- Environment Park SpA (Italy)

- CEA Liten (France)

- Turin Politecnico (Italy)

- Hensel Recycling Gmbh (Germany)

- EKPO Fuel Cell Technologies GmbH (Germany)

- Aktsiaselts Elcogen (Estonia)

- RINA Consulting SpA (Italy)

- University of Ljubljana (Slovenia)

“Hensel Recycling is proud member of the BEST4Hy consortium, an innovative EU financed research project to recycle fuel cells and save precious resources: we are delighted to be on board and contribute,” says Anna Marchisio, Business Development Manager at Hensel Recycling.

This project has received funding from the Fuel Cells and Hydrogen 2 Joint Undertaking under grant agreement No 101007216. This Joint Undertaking receives support from the European Union’s Horizon 2020 research and innovation programme, Hydrogen Europe and Hydrogen Europe research.

"ReSi standard" recycling of PV modules

Together with the project partners of Fraunhofer IWKS, DKE and VDE, the research project "ReSi-Norm - Standardization of recycling processes for silicon solar modules" has been successfully completed in the last two years.

As part of the project, different processes for recycling PV modules were evaluated, compared and tested. A basic distinction is made between mechanical, thermal and chemical recycling processes. All three process principles have both advantages and disadvantages. However, in order to exploit the full potential of PV recycling, standards and norms should serve as guidelines for future recycling activities. Not only the recycling technology was considered, but also the dismantling, transportation and collection of end-of-life PV modules.

Under the leadership of the VDE, a working group developed a guideline entitled "Requirements for the recycling of crystalline silicon photovoltaic modules", which essentially contains the following elements:

- Dismantling and sorting for possible reuse as a used appliance

- Collection, logistics and transportation as old appliances

- Treatment, preparation for reuse, recycling and recovery of old modules

The guideline is part of VDE Notation 0042-13, which deals with the collection, logistics and treatment of waste electrical and electronic equipment (WEEE Directive). The publication of the application rule is planned for the beginning of 2024.

- Fraunhofer Research Institution for Materials Recycling and Resource Strategies IWKS

- VDE Renewables

- DKE German Commission for Electrical, Electronic & Information Technologies in DIN and VDE

- Hensel Recycling GmbH